When it comes to manufacturing precision metal parts, the choice of machining technology directly impacts the quality, efficiency, and cost-effectiveness we can achieve. That’s why many customers ask us up front about our CNC Swiss machining capabilities, with some wondering about the differences between Swiss machines and conventional lathe processes.

Essentially, the answer lies in how each platform handles workpiece support, which can have a significant impact on deflection and vibration. The highly abridged version is that Swiss CNC machines are optimized for small complex parts and thin workpieces, while traditional lathes are used for efficiently turning larger and/or less slender parts.

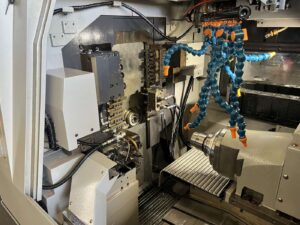

To understand why, let’s take a look under the hood of the Swiss lathe.

Precision Comes Down to Workholding

The most fundamental difference in Swiss machining vs. conventional turning is how the workpiece is held. Standard lathe setups support the material at its ends, typically in a chuck with the aid of a tailstock. While this arrangement is effective for larger, more rigid parts, insufficient lateral support can allow long, slender, and/or smaller workpieces to deflect under tool pressure.

Swiss CNC machines, by contrast, employ a sliding headstock combined with a guide bushing for the workpiece. This design supports the material extremely close to the cutting tool, minimizing vibration and deflection. The result is a highly stable machining process that is particularly well suited for producing thin, elongated, or intricately shaped parts.

If you want to learn more about the functional design of a Swiss turning machine vs. that of a conventional lathe, we have a basic rundown in our previous article: A Guide to Swiss CNC Machining: The Basic Anatomy of a Swiss Lathe

Maximizing Quality, Repeatability, and Machining Efficiency for Small Parts

There’s no doubt that modern CNC lathes of the conventional variety are extremely precise machines capable of manufacturing highly intricate parts. Nevertheless, Swiss CNC machines can take precision and repeatability to another level – especially on smaller diameters and/or exceptionally intricate part features.

For some designs, a Swiss lathe may be the only way to reliably reproduce such complex features. In other cases, better precision and repeatability simply means fewer rejected parts and less rework.

Swiss lathes also allow us to streamline the machining process with fewer setups. Thanks to live tooling, sub-spindles, and multitool configurations, we can often achieve single-cycle machining – completing all required operations in one setup. As we highlighted in a previous article Single-Cycle Machining with Swiss Lathes, this unique process shortens lead times, reduces handling errors, and increases throughput by minimizing secondary operations.

Basically, traditional lathes often require multiple setups across different machines, which can introduce delays as well as additional opportunities for part variation. For our customers, single-cycle Swiss machining means faster turnaround, more consistent parts, and a more streamlined path to finished product.

Swiss CNC Machining Services at Superior

At Superior Machining & Fabrication, we’re no strangers to the Swiss turning process. As an AS9100 certified aerospace manufacturer, one of our specialties is manufacturing precision aerospace hardware, fasteners, and related small parts utilizing our Swiss lathes. Learn more in our previous article: Swiss Machining for High-Precision Hardware

On that note, you’ve come to the right place to learn more about Swiss CNC machines:

- Learn about the invention and unique history of Swiss screw machines / lathes, taking you from Switzerland in the 1870s to our shop today: A Brief History of Swiss Turning Machines – The Invention of the Swiss Lathe

- Or you can learn about the general advantages that Swiss turning services offer to your products, especially for complex small parts: CNC Swiss Turning Services – Advantages and Common Machining Application

A Leader in CNC Machining within the Muenster, Texas Region and Beyond

At Superior Machining & Fabrication, we’ve invested in Swiss CNC technology because it delivers real, measurable value to our customers. Whether your project calls for complex Swiss turned parts or conventional milled/turned components, we have you covered with 100+ CNC workstations ready for your products.